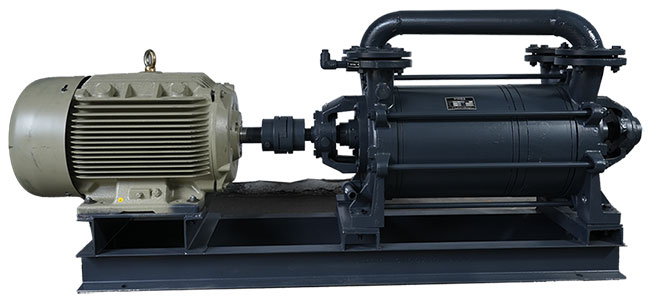

Two Stage Water Ring Vacuum Pump

Make Enquiry

Catalogue

Make Enquiry

Catalogue

Two Stage Water Ring Vacuum Pump / Double Stage Water Ring Vacuum Pump

We are leading manufacturer and exporter of a two-stage water ring vacuum pump; it is a type of vacuum pump that operates using the principle of a water ring. It's designed to create a vacuum by using water as a sealing and working fluid. The pump typically consists of double stages, each containing a series of blades or impellers that rotate within a casing.

Here's how it generally works:

- First Stage: In the first stage, the pump draws in the gas or vapor to be evacuated. As the impeller rotates, it creates a rotating ring of water inside the casing. This water ring forms a seal between the impeller blades and the casing, effectively trapping the gas or vapor.

- Compression: As the impeller continues to rotate, the volume of the gas trapped between the impeller blades decreases, leading to compression. This compression increases the pressure of the gas, pushing it towards the second stage.

- Second Stage: The compressed gas enters the second stage of the pump, where the process repeats. Another impeller further compresses the gas, increasing the pressure even more.

- Discharge: Finally, the gas exits the pump at a higher pressure than when it entered, leaving behind a partial vacuum within the system.

The use of two stages allows for higher levels of compression and greater efficiency compared to single-stage water ring vacuum pumps. This makes them suitable for applications where a deeper vacuum is required, such as in industries like chemical processing, pharmaceuticals, food packaging, dairy, pulp and paper. Additionally, the use of water as a working fluid provides advantages such as non-contamination of the pumped gas and the ability to handle condensable vapors.